HOME | home

About the Artists | Custom Design | Custom Pieces | Custom Pieces 3 | Lost Wax Casting | Celtic Pewter | Pewter History

Lost Wax Casting

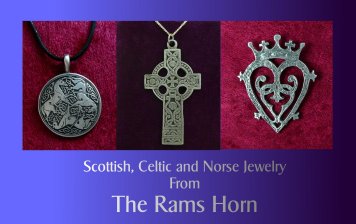

The Rams Horn

3680 Panama Stedman Road

Mayville, NY 14757

Phone 716-789-5804

"Old World Craftsmanship for Today"

The first people to utilize the lost wax process is unknown as it is shrouded in history. It is well documented that it has been used for thousands of years to produce objects in metal which could not be produced any other way, due to the complexity of their design. The lost wax process allows anything that can be modeled in wax to be accurately transmuted into metal. Most fine jewelry made from gold and sterling are made using lost wax casting as it produces the highest detail.

Sterling Silver Brooch by James E. Boyle

Hand carved original wax model by James E. Boyle

To begin the process of creating a new piece James or Beth work out a new design first on the drawing board. Working from photographs and sketches they create the initial model in green jeweler's wax. The method of Lost Wax casting we use at The Rams Horn is called "investment" casting. We use this method for the Sterling silver we cast while we depend upon spin casting for our pewter line. The investment mold material is made using gypsum plaster (plaster of Paris) as a binder for sand, silica flour, or another refractory aggregate. The dry ingredients are mixed with water and poured into a container or "flask" surrounding the sprued up model, which is either waxed down to a board or attached to a commercially available rubber device which holds the pattern and flask. Jewelry flasks are placed in a vacuum chamber while this mixture is still fluid, where they are boiled at room temperature to remove air bubbles clinging to the models. We also use this vacuum to de-air the investment mixture before pouring it over the wax models to reduce boiling over when vacuuming.

From this cast sterling original , the rubber mold is then made.

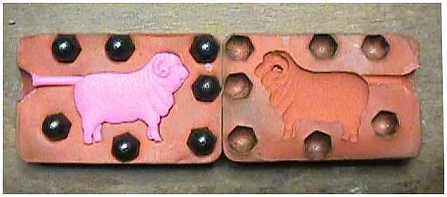

Here is the Merino Sheep brooch design in duplicate wax still in the rubber mold.

The wax patterns are carved meticulously with dental tools from special sculpture waxes designed to hold fine detail to create each new jewelry piece. Jim and Beth create wonderfully detailed animals and objects of beauty in the method handed down for thousand of years. Multiple copies of a design may be made even though the wax pattern is lost in the initial burn out process. Modern synthetic rubbers have been developed which capture very fine detail and can flex to release undercut areas of a model. Wax injection is used instead of simple gravity pouring, and the use of a vacuum casting machine forces metal into the mold.

After it is made and touched up, the wax model or models are attached to a "pour cup", which is funnel shaped to channel the metal into the mold from the outside, using "sprues" made from rods of wax , and a venting system is made the same way to convey air and other gasses out of the mold when it is filled with hot metal. Once the model is set up with its gates and vents, it is surrounded with a material that will cover it smoothly when wet and withstand high temperatures when fired in the kiln. This process is called investing.

Multiple waxes are then sprued into a tree for casting in Sterling Silver to put the piece into production.

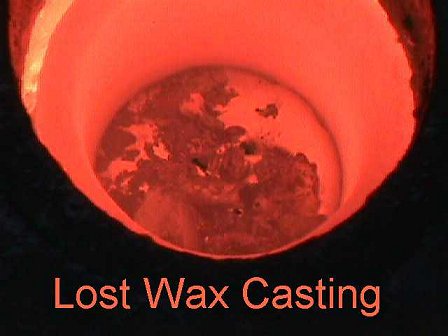

The gas furnace where the silver is melted.

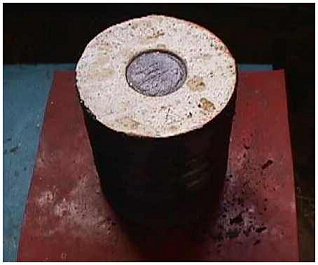

Once the plaster mixture (investment) has set hard, the flasks are placed in a kiln, slowly heated to between 1000 and 1250 degrees F, and held at that temperature until all wax residues have disappeared. The place where the wax was is now a void, hence the "lost wax" designation for this process. The metal is then melted in our metal furnace and the molds are filled with liquid silver or bronze that is poured by hand while the mold is still very hot. The flask is then allowed to cool and the investment mold is broken away revealing the metal piece. This process faithfully reproduces every detail of the original wax as well as the gates and vents, which must latter be cut off with a jeweler's saw. Silver, Brass, and Bronze may be used interchangeably with this method of casting.

The flask after casting, before the metal has cooled.

The multiple sheep brooches with investment still clinging to them just after casting.

Made in the USA

Thank you for your interest in our fine jewelry. We look forward to doing business with you. All of our metalwork is made right here in Western, NY. Our sterling jewelry is poured by hand by James Edward Boyle in sterling silver that is then hand finished and antiqued by hand in our studio. Our jewelry is signed and can be considered an investment in Fine Art. We Can produce custom designs for your business or organization using your design or we can design for you. Please write for a price quote. Let James or Beth design that very special project for you. Sterling silver has enduring beauty and our pieces can be passed down as heirlooms as each piece is a unique work of art.

Respectfully yours,

Jim and Beth

The Rams Horn

James Edward Boyle & Beth Maxwell Boyle

Established 1980

on the Web since 1997

copyright 2002 , Jim & Beth Boyle, All Rights Reserved

No part of this website may be used for any purpose ( including using images )

without written consent from The Rams Horn